Internal machine detection system

This test system device provides a refined solution for the production of internal electronic control boards, addressing product quality, operating status, performance parameters, data storage, and information management.

Detailed description

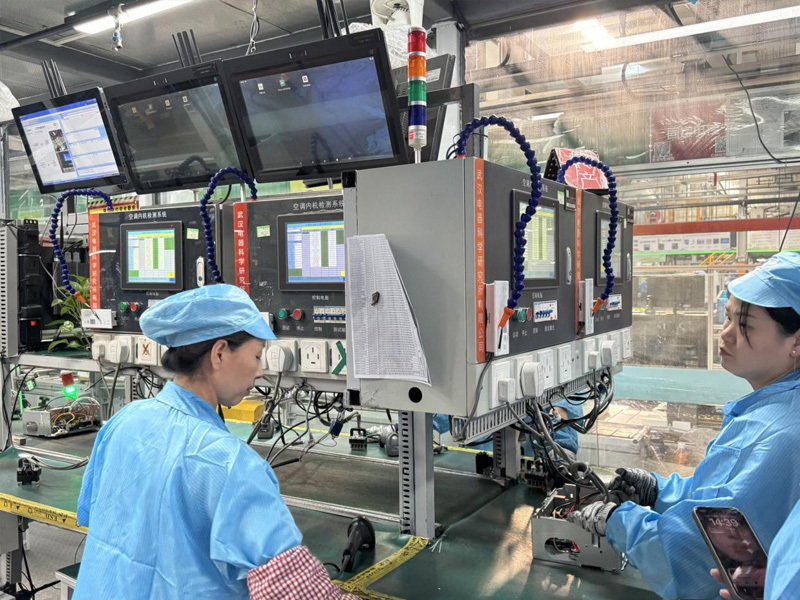

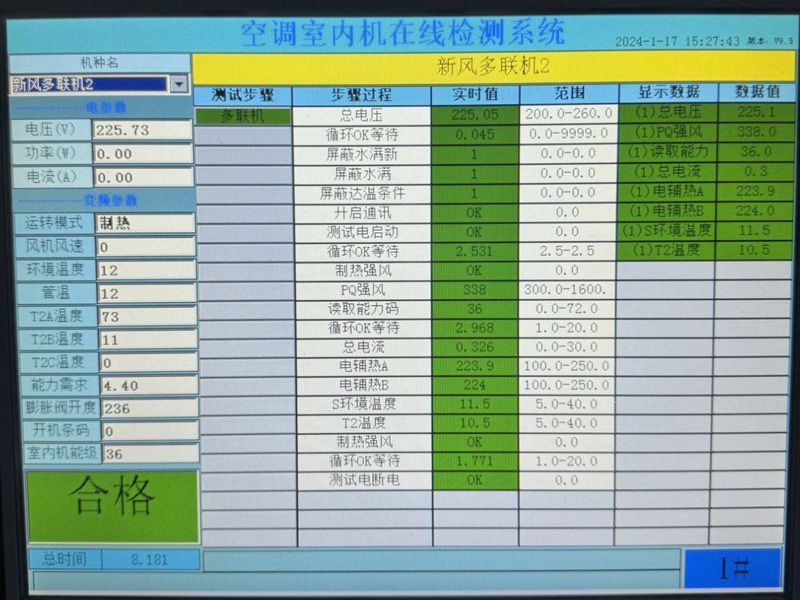

1.1 Indoor Unit Electrical Assembly Online Detection System

This testing system equipment mainly provides a refined solution for the production of indoor unit control boards, addressing product quality, operating status, performance parameters, data storage, and information management.

Operating Conditions

Operating time: 24 hours a day

Ambient temperature: -10—45℃, humidity ≤95%

Operating power supply: 220/380V, 50HZ. Voltage fluctuation range ±10%.

Relative humidity: 45%~95%; Compressed air: 0.4-0.55MPA

Technical Parameters

1. Operating voltage, current, and power of the whole machine heating (electric auxiliary heating) and cooling (strong, high, medium, and low wind)

Voltage 0-250V, accuracy ±(0.25% range + 0.25% reading)

Current 0-1/20A, accuracy ±(0.25% range + 0.25% reading)

Power 0-250W/5000W, accuracy ±(0.25% range + 0.25% reading)

2. Detection of output signals from the compressor, fan, four-way valve, etc.

3. According to the protocol provided by the manufacturer (variable frequency, remote control), the system can communicate with the indoor unit circuit board, read various monitoring parameters of the indoor unit system through communication, and control the operating status of the unit according to the set steps.

4. The system manages and monitors the testing process of each testing trolley, collects and saves the test data of each air conditioner, and can query and print the test results by barcode or model.

Serial Number | Test Parameters | Number of Test Points at Workstation | Measurement Range | Measurement Accuracy | Remarks |

1 | Voltage | 1 | 10-230V | ±(0.25% range + 0.25% reading) |

|

2 | Current | 1 | 0-10A |

| |

3 | Power | 1 | 0.02-2.5kw |

| |

4 | Communication | 1 | Communication protocol provided by the client | ||

1.2 Indoor Unit Running Room Online Detection System

This testing system equipment mainly provides a refined solution for the overall operation of air conditioner indoor units, addressing product quality, operating status, performance parameters, data storage, and information management.

Operating Conditions

Operating time: 24 hours a day

Ambient temperature: -10—45℃, humidity ≤95%

Operating power supply: 220/380V, 50HZ. Voltage fluctuation range ±10%.

Relative humidity: 45%~95%; Compressed air: 0.4-0.55MPA

Technical Parameters

1. Operating voltage, current, and power of the whole machine heating (electric auxiliary heating) and cooling (strong, high, medium, and low wind)

Voltage 0-250V, accuracy ±(0.25% range + 0.25% reading)

Current 0-1/20A, accuracy ±(0.25% range + 0.25% reading)

Power 0-250W/5000W, accuracy ±(0.25% range + 0.25% reading)

2. Detection of output signals from the compressor, fan, four-way valve, etc.

3. According to the protocol provided by the manufacturer (variable frequency, remote control), the system can communicate with the indoor unit circuit board, read various monitoring parameters of the indoor unit system through communication, and control the operating status of the unit according to the set steps.

4. The system manages and monitors the testing process of each testing trolley, collects and saves the test data of each air conditioner, and can query and print the test results by barcode or model.

| Serial Number | Test Parameters | Number of Test Points at Workstation | Measurement Range | Measurement Accuracy | Remarks |

1 | Voltage | 1 | 10-230V | ±(0.25% range + 0.25% reading) |

|

2 | Current | 1 | 0-10A |

| |

3 | Power | 1 | 0.02-2.5kw |

| |

4 | Communication | 1 | Communication protocol provided by the client | ||

Keywords:

Intelligent Detection Business

0.25

power

test

range

system

More Business

Leave a message

Leave your contact information to get a free product quote

Note: Please fill in the above information correctly so that we can feedback the processing results to you as soon as possible!